The standard approach for an ammo hopper is to have a big container and at the bottom have an outlet tube. Generally there will be some motors involved in moving the BB’s and it agitating the hopper to prevent the bb’s clogging against each other.

The advantage of this hopper is that it is (theoretically) simple and has a large ammunition capacity. However the necessity of agitation and extra feeding systems add complexity.

I’m currently attempting to design a simpler hopper. My aim is to create a design that cannot jam and still has a fairly large ammunition capacity for it’s volume.

I’m opening this thread to see if any of you guys with experience in hopper design will shoot down the idea straight away (maybe there’s something I’ve missed).

A simple jam-free hopper is a single tube with a spring at the end. However, for 250 rounds of ammunition you need a hopper 6mm x 1500mm - not likely to fit on your mech.

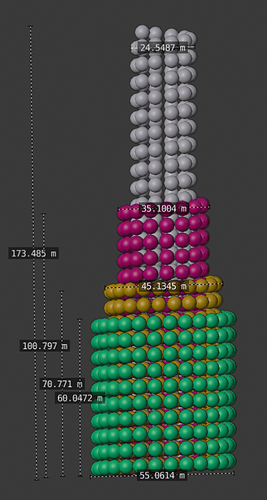

To fit in more BB’s, you can wind this tube into a spiral. Here are a couple of spirals each with 250 bb’s:

(all the units in the image should be mm rather than m, and I should have used proper dimension lines rather than just stretching the measuring tool by eye. Sorry). Probably the aspect ratio I’m happy with is a diameter of 45mm and a length of 70mm.

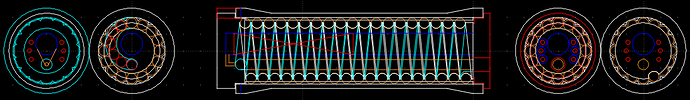

The problem with a spiral is that it’s hard to get a super long, super soft spring to go down the middle. Fortunately you don’t need a complete spiral, and can replace it with an outer-shell and an inner-shell. By rotating the inner shell, the BB’s can be made to move up or down the outer shell:

(Ignore the car-wheels-moving-backwards effect)

The rotation could be driven by a motor to allow rotating by exactly one bb size whenever you shoot, or it could be driven by a torsion spring (possibly a rubber band)

Essentially this is a recirculating ball-screw with the return channel going to the gun.

Possible further development:

In theory you could have an inner ball-race as well with the thread going the other direction. This would roughly double the capacity. Unfortunately the transition from the inner spring to the outer race to the inner race has to pass through the rotator. There probably is a solution for this but I haven’t managed to find one that didn’t require unmanufacturable parts.

Summary

Advantages:

- No agitator required

- Theoretically Can’t jam™

- 3d printable

- Operates in any orientation - upside down, on it’s side, etc.

Disadvantages:

- Lower ammo capacity per volume. If the loader is large enough, you could possibly put other things inside - the only needed space is around the edges.

- Pretty much only producible with 3D printer due to inside thread

- Have to load it one-rotation at a time (about 20 shots), and it’s hard to check how many are remaining by eye.

Do you guys foresee any issues with this design? How many bb’s do you guys go through in a fight (is 250 going to be enough)?

Unfortunately I don’t have any 6mm bb’s on hand, and due to CV-19 I can’t get any for the next month (or until whenever the lockdown ends), so this will almost certainly remain conceptual for the near future. I just wanted to throw this idea past some people who have some actual experience to see if they think it is worth pursuing.